Galvanizing Power Tower for Transmission Line

-

Price:

Negotiable

- minimum:

- Total supply:

-

Delivery term:

The date of payment from buyers deliver within days

-

seat:

Shandong

-

Validity to:

Long-term effective

-

Last update:

2017-11-15 17:26

-

Browse the number:

159

Company Profile

Company Profile

By certification [File Integrity]

Contact:Mr. Peter Zhou(Mr.)

Email:

Telephone:

Phone:

Area:Shandong

Address:Shandong

Website: http://sddctower.beitools.com/

Product Details

Product Description

SHANDONG DINGCHANG TOWER MANUFACTURING CO., LTD,which located in East of North Chengyang Road , Juxian , Rizhao City, Shandong Province, China, is a full service engineering and manufacturing company with a global reputation for delivering excellence and innovation in tower supply. Our company was founded in 2008. so we have more than 10 years of experience and innovation in engineering, designing, and building towers. It is a private enterprise producing various kinds of steel towers, including transmission tower, telecommunication tower,power tower and so on.

Along with the development of new project into production, our company has the adding total area of 330,792 square meters, as well as the total number of 1480 employees, including 210 engineering technical personnel. After the project is fully put into production, our company's annual comprehensive production capacity of towers can reach more than 200,000 tons.

Today, with more than 10 years of experience and our commitment to excellence, Dingchang remains an industry leader in the manufacture and design of steel tubular & angular & monopole structures for all Highway, Municipal, Custom, telecom, lighting and electric Utility applications.

We manufacture and supply all kinds of towers and posts or other steel structures for:

a. Telecoms

b. Power transmission

c. TV and Radio Broadcast

d. Roads and City Development

we main manufacture the towers with the following voltage:10kv, 35kv, 66kv, 110kv, 132kv, 220kv, 230kv, 330KV, 400kv, 500kv, 750kv, 800kv, 1000kv, 1100kv

towers including angular tower, tubular tower; SST tower and guyed tower; Single circuit tower, double circuit tower and multi - circuit tower; Lattice tower or monopole tower; H- frame, M-type tower, T-type tower, Y-type tower; And every type of utility poles, transmission &distribution poles, switch poles; Substation frameworks etc.

Our complete selection of towers includes:

a. Self-supporting tower

b. Monopoles

c. Steel tube tower

d. Custom-designed towers

e. transmission steel towers(10kV-1000kV)

f. Power transmission tower

Dingchang is one of the few manufactures who assemble a face of every tower section. This attention to quality and price. After fabrication all power transmission steel towers are delivered to the galvanizing facility to be Hot DiP Galvanized. Towers are processed through the facility by Caustic Cleaning, Pickling, and then Fluxing. These strict procedures insure years of maintenance free towers. Our company's power transmission steel towers systems can accommodate a variety of cross-arm. \

Other information:

Steel grades

Tower legs: Chinese steel Q345B, which same to ASTM A572 GR50

Other webs, bracing and not stress plate and angle steel: Chinese Q2230B, which same to ASTM A36

Plates: Chinese steel Q345B, which same to ASTM A572 GR50

Bolts: Chinese grade 6.8 and 8.8, which similar to ASTM A394

A) Dimension and tolerance for angle are according to GB/T1591-1994, similar to EN 10056-1/2

B) Hot dip galvanization in accordance with GB/T 13912-2002, which similar to ASTM A 123

C) The welding will be performance in accordance with AWS D1.1 or CWB standard

If client have other requirements, we can design according to client technical specification and requiremetns.

The main process of tower manufacturing

Here is fabrication process for our transmission tower; however, both parties must discuss all drawings and confirm all shop drawings, technical specification, and which standard to conform.

Before mass production, we must received all signed approved shop drawings and technical documents from our client.

Our Fabrication shall be in strict accordance with detail Drawings prepared by the Contractor and approved by the Engineer. Fabrication shall begin after the approval of the shop assembly and tests.

Shearing

Shearing and cutting shall be performed carefully and all portions of the work which will be exposed to view after completion shall be finished neatly. Manually guided cutting torches shall not be used.

All material over 13 (or 12) mm thick shall be cold sawn or machine flame cut.

Cropping or shearing shall be allowed for material thickness of 13 mm or less.

Flame cutting of high yield steel shall be preceded by a slight preheat operation by passing the cutting flame over the part to be cut.

All flame-cut edges shall be ground clean.

Bending

Our company owaned the bending machince. Frether more, we can manufacture the towers with hot bending or cold bending according to client's requirements.

Welding

No welding shall be done unless prior approval has been obtained from the Engineer.

Welding shall not be allowed at tower attachment points for conductor, shieldwire, insulators or associated assemblies or brackets.

Sub-punching

All holes in structural steel less than 10 mm thickness may be punched to full size unless otherwise noted on the approved Drawings. Holes shown on the Drawings as drilled holes and all holes in structural steel 10 mm or more in thickness and tension members of crossarms shall be drilled or sub-punched and reamed.

All holes shall be clean cut and without torn or ragged edges. All burrs resulting from reaming or drilling shall be removed. All holes shall be cylindrical and perpendicular to the member.

Where necessary to avoid distortion of the holes, holes close to the points of bends shall be made after bending.

Punching

For punching to full size, the diameter of the punch shall be 1.0 mm larger than the nominal diameter of the bolt, and the diameter of the die shall not be more than 1.5mm larger than the diameter of the punch. For sub-punching, the diameter of the punch shall be 4 mm smaller than the nominal diameter of the bolt, and the diameter of the die shall be not more than 2 mm larger than the diameter of the punch. Sub-punching for reamed work shall be such that after reaming no punch surface shall appear in the periphery of the hole.

Hole Size

Where holes are reamed or drilled, the diameter of the finished hole shall be not greater than the nominal diameter of the bolt plus 1.0 mm.

Galvanizing

All material shall be hot-dip galvanized after fabrication in accordance with the latest revision of GB/T 13912-2002 or ASTM Specification A 123.

Material that has been rejected because of bare spots or other coating defects shall either be stripped and re-galvanized, or the uncoated areas shall be recoated by an approved method.

All plates and shapes which have been warped by the galvanizing process shall be straightened by being re-rolled or pressed. The material shall not be hammered or otherwise straightened in a manner that will injure the protective coating.

Approval shall be secured from the Engineer if galvanizing is done outside of the Contractor's plant.

All galvanized steelwork shall be protected against white storage stain by using an approved dichromate solution treatment immediately following galvanizing.

Packing

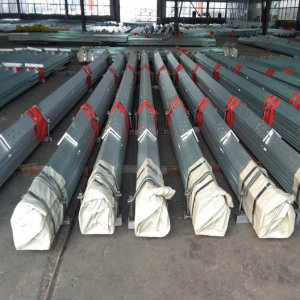

usually, we pack the angle steel tower in bundle

Along with the development of new project into production, our company has the adding total area of 330,792 square meters, as well as the total number of 1480 employees, including 210 engineering technical personnel. After the project is fully put into production, our company's annual comprehensive production capacity of towers can reach more than 200,000 tons.

Today, with more than 10 years of experience and our commitment to excellence, Dingchang remains an industry leader in the manufacture and design of steel tubular & angular & monopole structures for all Highway, Municipal, Custom, telecom, lighting and electric Utility applications.

We manufacture and supply all kinds of towers and posts or other steel structures for:

a. Telecoms

b. Power transmission

c. TV and Radio Broadcast

d. Roads and City Development

we main manufacture the towers with the following voltage:10kv, 35kv, 66kv, 110kv, 132kv, 220kv, 230kv, 330KV, 400kv, 500kv, 750kv, 800kv, 1000kv, 1100kv

towers including angular tower, tubular tower; SST tower and guyed tower; Single circuit tower, double circuit tower and multi - circuit tower; Lattice tower or monopole tower; H- frame, M-type tower, T-type tower, Y-type tower; And every type of utility poles, transmission &distribution poles, switch poles; Substation frameworks etc.

Our complete selection of towers includes:

a. Self-supporting tower

b. Monopoles

c. Steel tube tower

d. Custom-designed towers

e. transmission steel towers(10kV-1000kV)

f. Power transmission tower

Dingchang is one of the few manufactures who assemble a face of every tower section. This attention to quality and price. After fabrication all power transmission steel towers are delivered to the galvanizing facility to be Hot DiP Galvanized. Towers are processed through the facility by Caustic Cleaning, Pickling, and then Fluxing. These strict procedures insure years of maintenance free towers. Our company's power transmission steel towers systems can accommodate a variety of cross-arm. \

Other information:

| Material | Chinese material or as per clients requirement Q235,Q345,Q390,Q420 etc. |

| Packing | in bundle or according to client's requirements |

| Minimum order | 10 tons |

| Payment terms | 30% T/T in advance or L/C or others you needed. |

| Delivery time | 20-35 days after the drawings and prepayment |

| Price | FOB Qingdao Port USD: 950-1100/ton or any port of China you specifiedCRF and CIF is also available. |

| Port of Loading | Qingdao Port |

| Availability size | Based on the customer's requirements. |

| Fabrication standard | Chinese Standard (GB) or other standard which client accepted |

Steel grades

Tower legs: Chinese steel Q345B, which same to ASTM A572 GR50

Other webs, bracing and not stress plate and angle steel: Chinese Q2230B, which same to ASTM A36

Plates: Chinese steel Q345B, which same to ASTM A572 GR50

Bolts: Chinese grade 6.8 and 8.8, which similar to ASTM A394

A) Dimension and tolerance for angle are according to GB/T1591-1994, similar to EN 10056-1/2

B) Hot dip galvanization in accordance with GB/T 13912-2002, which similar to ASTM A 123

C) The welding will be performance in accordance with AWS D1.1 or CWB standard

If client have other requirements, we can design according to client technical specification and requiremetns.

The main process of tower manufacturing

Here is fabrication process for our transmission tower; however, both parties must discuss all drawings and confirm all shop drawings, technical specification, and which standard to conform.

Before mass production, we must received all signed approved shop drawings and technical documents from our client.

Our Fabrication shall be in strict accordance with detail Drawings prepared by the Contractor and approved by the Engineer. Fabrication shall begin after the approval of the shop assembly and tests.

Shearing

Shearing and cutting shall be performed carefully and all portions of the work which will be exposed to view after completion shall be finished neatly. Manually guided cutting torches shall not be used.

All material over 13 (or 12) mm thick shall be cold sawn or machine flame cut.

Cropping or shearing shall be allowed for material thickness of 13 mm or less.

Flame cutting of high yield steel shall be preceded by a slight preheat operation by passing the cutting flame over the part to be cut.

All flame-cut edges shall be ground clean.

Bending

Our company owaned the bending machince. Frether more, we can manufacture the towers with hot bending or cold bending according to client's requirements.

Welding

No welding shall be done unless prior approval has been obtained from the Engineer.

Welding shall not be allowed at tower attachment points for conductor, shieldwire, insulators or associated assemblies or brackets.

Sub-punching

All holes in structural steel less than 10 mm thickness may be punched to full size unless otherwise noted on the approved Drawings. Holes shown on the Drawings as drilled holes and all holes in structural steel 10 mm or more in thickness and tension members of crossarms shall be drilled or sub-punched and reamed.

All holes shall be clean cut and without torn or ragged edges. All burrs resulting from reaming or drilling shall be removed. All holes shall be cylindrical and perpendicular to the member.

Where necessary to avoid distortion of the holes, holes close to the points of bends shall be made after bending.

Punching

For punching to full size, the diameter of the punch shall be 1.0 mm larger than the nominal diameter of the bolt, and the diameter of the die shall not be more than 1.5mm larger than the diameter of the punch. For sub-punching, the diameter of the punch shall be 4 mm smaller than the nominal diameter of the bolt, and the diameter of the die shall be not more than 2 mm larger than the diameter of the punch. Sub-punching for reamed work shall be such that after reaming no punch surface shall appear in the periphery of the hole.

Hole Size

Where holes are reamed or drilled, the diameter of the finished hole shall be not greater than the nominal diameter of the bolt plus 1.0 mm.

Galvanizing

All material shall be hot-dip galvanized after fabrication in accordance with the latest revision of GB/T 13912-2002 or ASTM Specification A 123.

Material that has been rejected because of bare spots or other coating defects shall either be stripped and re-galvanized, or the uncoated areas shall be recoated by an approved method.

All plates and shapes which have been warped by the galvanizing process shall be straightened by being re-rolled or pressed. The material shall not be hammered or otherwise straightened in a manner that will injure the protective coating.

Approval shall be secured from the Engineer if galvanizing is done outside of the Contractor's plant.

All galvanized steelwork shall be protected against white storage stain by using an approved dichromate solution treatment immediately following galvanizing.

Packing

usually, we pack the angle steel tower in bundle