Rotary Screw Type Air Compressor

-

Price:

Negotiable

- minimum:

- Total supply:

-

Delivery term:

The date of payment from buyers deliver within days

-

seat:

Beijing

-

Validity to:

Long-term effective

-

Last update:

2024-02-11 03:42

-

Browse the number:

221

Company Profile

Company Profile

By certification [File Integrity]

Contact:cqnl2021(Mr.)

Email:

Telephone:

Phone:

Area:Beijing

Address:Beijing

Website:http://www.cq-endurance.net/ http://cqnl2021.beitools.com/

Product Details

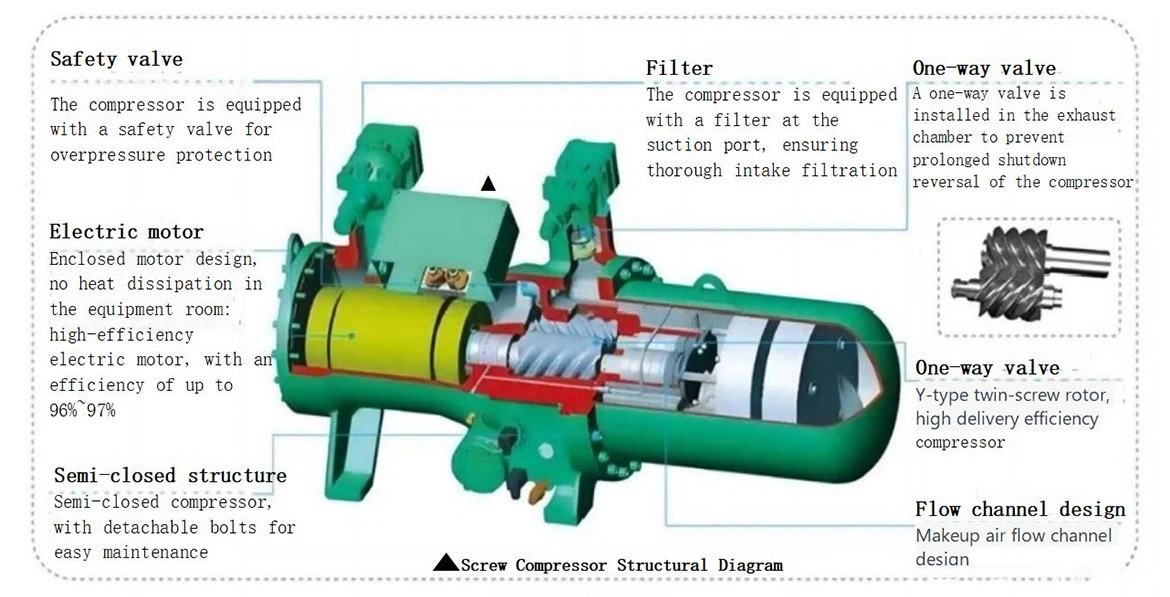

A rotary screw type air compressor is mainly composed of a pair of parallel, intermeshing rotors (screws) that rotate in opposite directions. This construction makes it the most widely used type of rotary compressor. The screw compressor is a dual-shaft positive displacement rotary compressor, and the number of meshing teeth determines its volumetric efficiency and compression efficiency. In operation, the principle of the screw compressor involves the periodic variation of working volume through the rotation of rotors inside the casing, thereby achieving gas compression. The oil injection amount in this compressor is usually proportional to its rotational speed, allowing for performance adjustment by regulating the oil injection amount.

Â

Â

Features:

Â

1,Compared to reciprocating piston refrigeration compressors, rotary screw type air compressor have a series of advantages such as high speed, light weight, small size, compact footprint, and low exhaust pulsation.

2,Compressors lack reciprocating mass inertia, exhibit good dynamic balance performance, operate smoothly, have minimal base vibration, and can be installed on smaller foundations.

3,The rotary screw type air compressor is simple, with fewer components and no vulnerable parts like valves or piston rings. The main friction components, such as rotors and bearings, have high strength and wear resistance. Additionally, the lubrication conditions are favorable, resulting in lower machining requirements, reduced material consumption, long operating cycles, reliability, simple maintenance, and ease of achieving automation.

4,Compared to speed-type compressors, screw-type compressors feature forced gas discharge, meaning the volumetric efficiency is almost unaffected by discharge pressure. They do not experience surge phenomena at low discharge volumes and can maintain high efficiency across a wide range of operating conditions.

5,Incorporating slide valve regulation allows for continuous energy adjustment.

6,Compressors are not sensitive to liquid inlet conditions and can utilize oil injection cooling. Therefore, at the same pressure ratio, they have much lower discharge temperatures compared to piston-type compressors, resulting in a higher single-stage pressure ratio.

7,With no clearance volume, screw compressors exhibit high volumetric efficiency.

Â

Specification

Â

Â

The unit adopts a twin-screw main engine, and the device is mainly composed of seven parts:

1,Compressor (twin-screw main engine)

2,Power system (driven by natural gas engine or electric motor)

3,Cooling system

4,Inlet filtration system

5,Oil and gas separation system

6,PLC control system

7,Pipelines and valves

Qualification

Â

Â

http://www.cq-endurance.net/